The client is a well known client in the area that is adding on due to unprecedented growth. They have both mechanical and electrical/panel wiring positions.

They are willing to train someone who has a little bit of assembly experience, all the way up to taking on a more senior team member and the starting wages show that.

Mechanical: Must be able to read blueprints, work instructions and know how to use hand and power tools. Someone that knows soldering and/or brazing or welding would be a plus!

Electrical: Prior experience wiring machines and/or panels, reading schematics and knowing point to point wiring is a plus

Hours are typically 6am until 2:30pm or you can work 4-10's also!!! Plus, they will be flexible for the right person so if a 5am or 7am start works better, that could work.

Starting wage is anywhere between $18 and $25/HR depending on experience and the particular department

Job Features

| Job Category | Manufacturing |

- Ability to work in a fast-paced, high-speed environment, follow standardized work and adhere to safe work practices in a continuous improvement environment

- Experience in a manufacturing environment is a plus

- Perform necessary pre-operation activities to ensure proper equipment startup and operation on multiple pieces of equipment

- Operate/monitor multiple pieces of equipment during operation to ensure quality production and minimal unplanned stops

- Communicate with team members and support teams to ensure continuous production of the correct product at high quality levels with minimal wasted time and materials

- Housekeeping and sanitation

- Assist in the progression of training and planned development of all machinists.

- Perform other duties as assigned.

- Experience as a Machine Operator

- Knowledge of Production Procedures

- Ability to Read Blueprints, Schematics and Manuals

- Analytical Skills

- Attention to Detail

- Teamwork

- Physical Stamina and Strength

- Handle Heavy Equipment

- Work Independently

- Multitask

Job Features

| Job Category | Manufacturing |

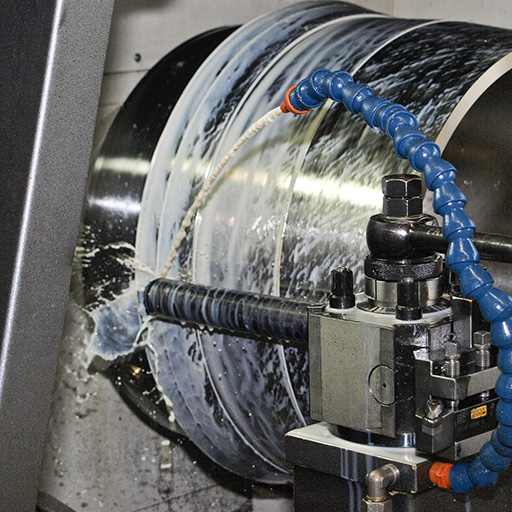

- Set up and operate CNC Mill(s) to perform various machine functions such as; milling, turning, boring, recessing, and occasional profiling or contouring of metallic and nonmetallic work-pieces.

- Set-up, create, check programs and operate automatic numerically controlled machine tools.

- First piece and in process inspections of parts produced.

- Work from operational data to define tooling, fixturing, and machine arrangements.

- Recommend tooling arrangements, fixtures, and operational sequences, etc.

- Use a variety of precision measuring instruments.

- General knowledge of machine shop practices and techniques, machine operation and tooling.

- Must have a basic understanding and knowledge of injection molding process, equipment and materials. The addition of other molding processes is helpful.

- Completion of a state indentured tool and die apprenticeship, CNC Machinist apprenticeship or accrued experience.

- Must be able to read and understand blueprints, specifications and routings.

- Ability to add, subtract, multiply, and divide in all units of measure, using whole numbers, common fractions, and decimals.

- Minimum of 2 years experience.

- High School diploma or GED.

- Positive attitude

Job Features

| Job Category | Manufacturing |

Job Features

| Feature 1 | Feature description |

| Feature 2 | Feature description |

| Feature 3 | Feature description |

- Routinely inspecting electrical systems such as wiring, fixtures, and appliances.

- Identifying faults or hazards.

- Troubleshooting system failures.

- Reviewing blueprints to understand wiring placement.

- Testing of electrical systems with oscilloscopes, voltmeters, and ohmmeters.

- Conducting maintenance repairs on old or faulty fixtures.

- Responding to fault requests.

- Providing suggestions for equipment replacement.

- Writing electrical maintenance reports.

- Installing new electrical appliances in the building.

- Adhering to safety and performance standards.

- High school diploma or GED.

- Electrician qualification certificate.

- Proven work experience as a Maintenance Electrician.

- Familiarity with industrial electrical systems and the National Electrical Code.

- Good problem-solving skills.

- Physically strong and able to stand for long periods.

- Good communication skills.

Job Features

| Job Category | Manufacturing |

- Operate machinery, equipment, and computer terminals

- Test, Troubleshoot and correct panel

- Make sure wires are tie wrapped and neatly inserted in enclosures.

- Complete electrical panels on time

- Machine wiring “a huge plus”

- Visually inspect and reject parts outside of written specifications

- Effectively wire a variety of products that range from standardized design and function to non-standard products

- Operate within standard operating procedures (SOPs), position overview, wiring diagrams, schematics, blue prints, and work instructions

- Use proper tools as needed to crimp wires and create harnesses

- Complete daily production and quality logs and labor cards

- High school diploma or equivalent, with a preference for trade school training and/or 1+ years of related experience

- Experience using Electrical Schematics

- Proven electrical and mechanical aptitude

- Knowledge of Quality inspection principles

- Use of hand tools, power tools, and electrical testing equipment

- Self-starter and willing to accept new challenges

Job Features

| Job Category | Manufacturing |

- Repairs and maintains school buses and school bus equipment.

- Test drives repaired equipment.

- Oils and greases vehicles; changes filters.

- Basic computer skills in order to navigate in ISIS for diagnostics

- Knowledge of basic engine and driveline

- Knowledge of basic electrical

- Knowledge of cab and suspension

- Trailer preventative maintenance work

- Knowledge of air, hydraulic, and full power brake systems

- Knowledgeable of medium and heavy duty truck product

- Inspection and lubrication

- Cab, frame front axle, steering gear & springs

- Brake system, air and hydraulic

- Notifies supervisor of potentially dangerous equipment and corrective action taken.

- Performs all other duties as assigned.

- Be at least 18 years of age

- Have a valid driver’s license

- Have or be able to obtain a CDL license

- Subject to a background check and drug screen

- Possess a combination of education and technical experience including a minimum of 3 years diesel service and fleet experience

- ASE Diesel Certifications Strongly Preferred (Must be able/willing to obtain)

- High Value on Master Level Diesel Techs

- Setup CNC turning centers for production turning.

- Troubleshoot and optimize new production programs to ensure efficient overall production.

- Document new programs and processes to ensure setups can be duplicated and overall production time is optimized.

- Oversee the quality of parts produced in the machining cell.

- To share expertise and knowledge throughout the machine shop and be a focal point for advice on machining operations

- To use skills to protect against potential damage to all machines and in particular to take overall ownership of the machine cell.

- To be proactively aware of work load and plan tooling requirements for future jobs ensuring minimum downtime.

- To make most efficient use of machinery and equipment, including the use of proper feeds and speeds.

- Inspect and deburr parts to ensure they meet blueprint specifications using proper measuring instruments.

- Produce jigs and fixtures that improve productivity.

- Implement daily and weekly maintenance programs on machine shop equipment

- Follow all safety policies and procedures.

- Assist in the progression of training and planned development of all machinists.

- Setup machines on a flexible basis to ensure optimum output throughout the shop.

- Perform other duties as assigned.

- Must have a basic understanding of CNC machining work and tool offsets.

- Must be able to identify critical blueprint dimensions and instruct workers how to inspect and check these critical dimensions.

- Ability to work on a wide variety of complex parts from drawings.

- Ability to change and adapt work behaviors based on a constantly changing production schedule.

- Must have basic computer skills including Microsoft Word, Excel, and Windows.

- Must have basic understanding of ISO 9001 and quality principles.

- Must be dependable and detailed oriented.

Job Features

| Job Category | Manufacturing |